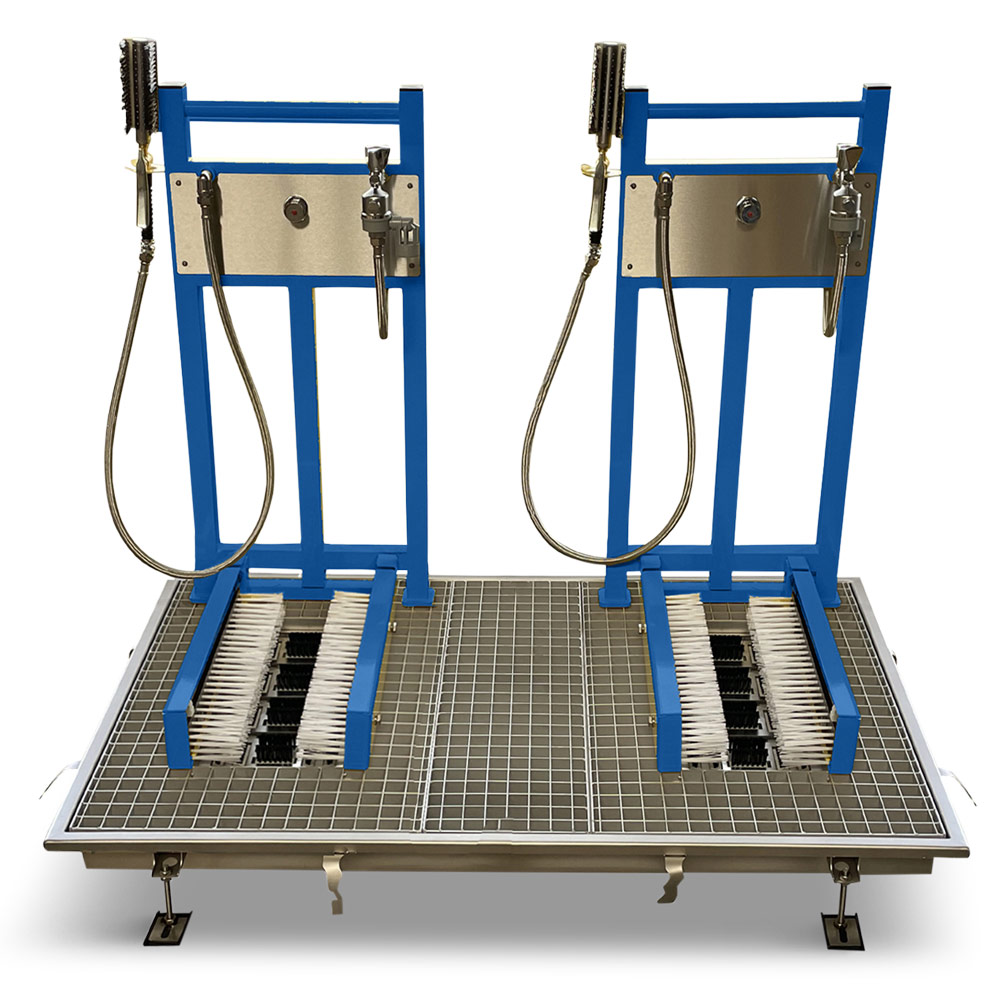

Boot washer steel flush to the floor flat

Sales price without discount:

from Price on request GBP plus VAT (depending on option)

- Professional boot washer made of stainless steel

- Extra flat design for partially recessed or ground level installation

- Up to 2 cleaning stations in one boot washing system

- For daily, professional service in the fire brigade and in the fire station

- With built-in system separator according to DIN EN 1717 to protect the water quality

- With water-guiding hand brush for precise cleaning of boot shafts

- With practical retaining bracket

- Stainless steel tub and floor drain, sludge trap and odour trap

- Further product description and technical data

Request a customised quote

Please complete the form and we will send you our offer, including a description, images and technical data, within 1-2 days.

Description

This boot cleaner, made of stainless steel, can be installed partially recessed or at ground level in floors. There it then ensures reliable, precise cleaning of all boots every day. Depending on requirements, the boot washer can be ordered with one or even two washing stations. Thanks to the extra-flat design with an installation depth of 90 mm, an extremely flat installation is possible. In the centre of the floor of the stainless steel tub is a drain with sludge trap and odour trap, all made of one hundred percent stainless steel.

The boot cleaning system's easily removable grids contain the entire technology, including the effective side brushes, sole brushes and side water spray nozzles made of stainless steel. Thanks to these robust components, boots are accurately cleaned from sole to ankle height. Above the grids there is a stainless steel bracket that ensures a safe stand and quick use of the boot washer. The bracket contains the included self-closing valve for automatic water control and a protective system separator in accordance with DIN EN 1717. The high-quality water-carrying hand brush can be inserted into the side of the bracket and allows even more precise cleaning of the boot shafts or other objects.

The boot washer stainless steel built-in version flat unfolds its full potential especially in the fire brigade, in troop accommodation and commercial as well as agricultural enterprises.

With the following features, the "boot washer stainless steel built-in version flat" is convincing in professional use:

- Boot washer made of high-quality, stainless steel

- 1 to 2 places - Available with one or two cleaning places (see options)

- Including "system separator BA" of liquid class FK 4 according to DIN EN 1717 for maintaining water quality

- For deep or flush installation in floors

- Extremely shallow installation possible (installation depth 90 mm)

- Several lateral brushes for precise cleaning of boots up to and including ankle height

- With 12 easily replaceable sole brush strips

- Side-mounted stainless steel spray nozzles

- Automatic water stop valve incorporated in the grab rail

- Stainless steel tray with central floor drain, sludge trap and stainless steel odour trap

- Removable stainless steel grate

- With stainless steel hand support for more stability

- Supplied with water-guiding hand brush incl. 1.5 m long metal flex hose

- Adjustable feet made of stainless steel for easy installation

- Easy cleaning and maintenance

- No electricity connection necessary

With the hard sole brushes and the softer side brushes, the "boot washer stainless steel built-in version flat" cleans boots and ankle-high work shoes thoroughly and quickly. Soiled boots are placed on the boot rest with the sole brush strips. After manual operation of the water self-closing valve, the stainless steel spray nozzles on the side, above the side brushes, wet the footwear all around with liquid. The friction of the boots against the 12 bottom brushes and the 2 side brushes effortlessly removes dirt from the surface, leaving the shoe material sparkling clean. Meanwhile, the powder-coated stainless steel grab rail invites you to hold on at the right height and secures every stance. On the left-hand side is a water-carrying hand washing brush incl. 1.5 m armoured hose with a quick-action valve and rinsing tube made of stainless steel to make boot cleaning even more individual and precise. Also integrated in the mounting bracket is a certified system separator according to DIN EN 1717 for maintaining water quality. The boot cleaning system is available in two different versions and sizes, with one washing area or with double capacity and two boot cleaning areas.

A central drain in the stainless steel tray with integrated sludge trap bucket and odour trap, allows for smooth water drainage and protects against odours from the drainage system. The grids, just like the sole cleaning brushes of the boot cleaning machine, can be easily removed and replaced. This makes maintenance and cleaning particularly easy. The water connection must comply with the regulations of the local waterworks and must be carried out by an authorised specialist company. A power connection is not required.

Technical specifications

Housing: stainless steel 1.4301 with powder-coated retaining bracket

Dimensions (1 cleaning place):

574 mm x 874 mm x 90 mm (width x depth x height)

Dimensions (2 cleaning places):

1350 mm x 874 mm x 90 mm (width x depth x height)

Height of retaining bracket: 980 mm

Installation depth: 85-90 mm

lateral levelling feet: 2x 60 mm

Water inlet (per wash place): KW R1/2" with shut-off

Water drain: NW 100, central

Operating pressure (per wash place): 2-6 bar

Power supply: not necessary

Warranty: 2 years